25 years of experience in vibration isolation Keeps You STable

Optical Table, Vibration Isolation Table and Support Systems

The Parts of the STable Active Pneumatic Vibration Isolation Tables

STable Active Pneumatic Vibration Isolation Table has got four legs and a top plate (in other words it is table top). The legs are assembled together with strong horizontal beams. We call this 4-leg structure leg system. Some competitors call it table support. They are the same. In every leg there is a pneumatic working cylinder on the top of the leg. These working cylinders form a virtual surface, on which the top plate is floating. The actual height of the pistons in the working cylinders are controlled by a pneumatic control system built on the valve assemblies. Physically the Active Pneumatic Vibration Isolation Table has got four legs, but logically it is a table with three legs. This feature gives an excellent stability on the three base points. This trick is realized on that way that the two legs on the front have got their own control systems each. But the two legs on the rear side of the Active Pneumatic Vibration Isolation Table are internally connected parallel and controlled by only one control system. This arrangement forms a virtual middle-position leg between the two rear legs.

Common Technical Data of the STable Active Pneumatic Vibration Isolation Tables

Vibration attenuators: 2nd-order, linear phase pneumatic filters are built into the working cylinders of the table. Applying the 2nd-order vibration damping filters highly improves the vibration attenuation performance. This kind of pneumatic filter is a unique feature, what is employed only in the STable Active Pneumatic Vibration Isolation Tables. This solution is not available at our competitors.

Cutoff frequency of the high-cut isolators: 10 Hz

Flatness error: +/- 0.25 mm per meter as maximum, along any straight line, anywhere on the top plate.

Horizontality error of the top plate on a working vibration isolation table (in other words the hysteresis of the height control): +/- 1.5 mm as maximum, measured between two opposite corners of the top plate, in worst case.

Gas supply: any kind of non-toxic, non-flammable, non-aggressive, non-corrosive gas (e.g. Nitrogen, compressed air). We recommend to use a Quiet Air Compressor (see below) as the simplest, cheapest and most secure gas supply. Please read the notes and warning below about using local air supply.

Working pressure ranges of the gas supply:

2.0 to 2.2 Bar for the "small" tables

5.0 to 7.0 Bar for the "large" tables

The absolute pressure limits of the gas supply:

2.5 Bar for the "small" tables

7.5 Bar for the "large" tables

Color of the leg system: RAL 5019. "Any color can be ordered as long as it is dark blue" (citation from Henry Ford. Every Model T was painted black).

Material of the membranes in the working cylinders: fine and durable silicone.

Height of the table top surface from the floor: 82 cm or more. The height depends on the thickness of the top plate, please see the details later.

Weight of the leg system:

120 kg for the Small Size tables

150 kg for the Large Size tables

250 kg for the 180 x 180 cm tables

Weight of the top plate depends on the size. For rough estimation (based on the surface, width x depth): 170 kg / m2

Earthquake-proof. There is no greater test than an unexpected circumstance life throws in our way. In the afternoon on 18th January, 2017 there was an earthquake, magnitude of 5.7 in Italy. Two pieces of STable Active Pneumatic Vibration Isolation Tables were operating approximately 120 km far away from the epicenter. Super resolution imaging processes was running on both tables (N-SIM on the first table and N-STORM on the other). We could feel the building shaking, but the imaging process was not disturbed, the picture quality remained excellent.

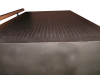

The internal structure of the top plate is a trussed rectangular crossbar structure (patented) made of welded carbon steel by default. As an option, full stainless steel top plate (even the internal structure) can also be ordered. Every top plate is covered by dull stainless steel surface (skin).

The skin (top surface) of the top plate is stainless steel alloy with special magnetic feature by default. It provides the possibility to fix objects with magnetic bases on the top plate. Optionally you can choose a bit better rust-proof material, but it does not have magnetic capability. Their prices are the same. If you need the optional skin material, please mention it in the order.

Default skin: less rust-proof alloy with magnetic feature. Its standard material code is 1.4016

Optional skin: highly rust-proof and acid-resistant alloy without magnetic feature. Its standard material code is 1.4301

Rigidity of the top plate: the deformation of a 180 x 149 cm top plate, if 2 kN concentrated force load is applied to its middle point: 12 microns (0.47 mil). We carried out the same measurement on a SmartTable UT top plate (manufactured by the worldwide most famous competitor firm, the name of that company is intentionally not mentioned). The deformation of the SmartTable was two times bigger on the same force load. So the result is: rigidity of our STable top plate is two times better than the worldwide most famous competitor’s rigidity.

Deformation of the top plate for temperature change: the deformation of a 180 x 149 cm top plate, measured in the middle, if mass load was not modified, but we increased the temperature with 10 Centigrade: 8 microns (0.3 mil). We carried out the same measurement on a SmartTable UT top plate, too. The self-deformation of STable top plate for temperature change was nearly three times better (three times smaller deformation). The unit weight (the weight referring to the same size) of STable top plates is approximately two times bigger compared to the worldwide most famous competitor's SmartTable UT top plates. But we will keep manufacturing of welded steel structure top plates, because we focus on the better performance instead of the lighter weight.

Metric M6 threaded holes drilled on the top plate in 25 x 25 mm pattern can be ordered as an option. As we call it this is optical hole pattern. Most of the customers require it. If you do not need this hole pattern on the top plate, in other words if you need a top plate without holes, you should specify it in the order. Other, user-specified hole arrangements, or special shaped, even big holes (e.g. for bottom or base port camera) can be ordered, as well.

You can order any size of table. The price of the leg system (in other words table support) is independent of the actual size. There is a fixed price for the "small" and another constant price for the "large" leg systems. The price of the top plate is proportional to its surface area. The smallest available size is 98 x 66 cm. Custom size of table does not mean harder price, only longer manufacturing time is necessary (because they are not in stock as the frequently sold models). The frequently sold (in other words our favorite) sizes of tables are:

980 x 660 mm

1100 x 800 mm

1200 x 900 mm

1500 x 980 mm

1800 x 1800 mm

The User Manual of the STable Active Pneumatic Vibration Isolation Tables is available for download.

The detailed Installation Manual and the abridged Steps of Installation leaflet of the Active Pneumatic Vibration Isolation Tables is available for download.

In connection with the optical tables there are many more useful documents available for download.

To help you to compare the products of different manufacturers we have to emphasize a funny terminological fact. In the documents and websites of our competitors you can find alternative product names. There are some minor differences between them. However it is fascinating, that all these terms basically mean the same as Vibration Isolation Table (we prefer this name). The frequently used synonyms are: Optical Table, Antivibration Table, Anti-Vibration Table, AV Table, Vibration Isolator, Vibration Isolation System, Optical Workstation, Isolated Platform, Isolation Platform, Vibration Isolation Platform, Pneumatic Table, Pneumatic Isolator, Air Table, Vibration Control System, Vibration-Free Table, Vibration Damping System, Vibration Damper, Isolation Frame, Active Vibration Isolator, Pneumatic Post, Active Post System, Laboratory Table, Lab Table, Vibration Isolation Workstation, Active-Air Table, Active-Air Legstand. What a confusion of words, who knows why?

Attenuation Diagram

You can download the worst case attenuation diagram of the STable Active Pneumatic Vibration Isolation Tables, measured on the vertical axis. In the diagram the relative attenuation is shown as a function of the frequency. During the measurements a vertical excitation was applied at the floor standing the Table on. The spectral characteristic of the excitation was a white noise. The measurements were carried out in the time domain, and then they were transformed off-line to the frequency domain.

This attenuation diagram was measured on an empty (nothing on the top plate) 980 x 660 mm Table. This is why the diagram shows the worst case situation. This statement means that in most of the real situations better performance can be measured than what this diagram shows. The corner frequency of the vibration isolator working cylinder is reciprocally proportional to the mass load on the working cylinder. On the one hand the bigger tables have heavier top plates. On the other hand there are always equipments installed on the top plate, increasing the total weight. The bigger mass results a lower corner frequency and as a result it gives better vibration attenuation performance above the corner frequency.

Active Pneumatic Vibration Isolation Tables (Small Size)

In our terminology "small" size means, if the top plate is smaller than or equals to 1.5 m2.

Thickness of the top plate: 110 or 170 mm (depending on the size).

Height of the top surface of the top plate from the floor depends on the thickness of the top plate. To compensate the flatness error of the floor, each legs are adjustable by +/- 6 mm. Below you can see the nominal heights:

Top plate thickness Height of the top surface (of the top plate)

110 mm 82 cm

170 mm 88 cm

For a "small" table, optionally, you can order Impala granite top plate. This is a very resistant and smart material, but it is a very difficult procedure to make holes on the surface of the granite plate. However we accept requirements for a few holes. The specification blueprint of the fixing holes on the granite plate should be received by us before starting the manufacturing process.

Maximum mass load of the legs: 4 kN, including the top plate.

Click on the picture to get it in

full size

Active Pneumatic Vibration Isolation Tables (Large Size)

In our terminology "large" size means, if the top plate is bigger than 1.5 m2.

Thickness of the top plate: 170 to 350 mm (depending on the size).

Height of the top surface of the top plate from the floor depends on the thickness of the top plate. To compensate the flatness error of the floor, each legs are adjustable by +/- 6 mm. Below you can see the nominal heights:

Top plate thickness Height of the top surface (of the top plate)

170 mm 88 cm

210 mm 92 cm

250 mm 96 cm

280 mm 99 cm

310 mm 102 cm

Maximum mass load of the legs: 8 kN, including the top plate.

In the pictures below you can see a large table with the optional "Optical Hole Pattern" on the top surface. Optical Hole Pattern means M6 metric threaded holes are drilled in 25 x 25 mm pattern. All other options and optional accessories are listed in the Price List. The options are extra features, they are not included in the default price.

Click on the picture to get it in full size

IVF Vibration Isolation Solutions

In 2020 Supertech Instruments launched a new line of products for IVF setups, developed together with microscopy specialists, IVF experts and end users. You can see the details of those products if you click on our IVF Vibration Isolation (IVF Table) page.

Popular Accessories of the STable Optical Tables

• Quiet Air Compressor / Air Pump

• Set of Casters (wheels). On the tables manufactured after 2022 they are default parts.

• Variable shelf system to the back and/or left and/or right sides of the table, with three pieces of 30 cm deep shelves

• Stainless steel bottom shelf

• Optical Hole Pattern

• Breadboard (47 mm thick steel sandwich plate with M6 threaded holes on it, in 25 x 25 mm pattern). We manufacture any user-defined size of breadboard

• Special shaped, even big hole on the top plate, according to your specification and/or drawing

• Additional arm rest with holder rod set and screws to the back, left or right side of the table (the front arm rest is a basic, free accessory)

• One piece of side shelf lain on the two arm rests, made of stainless steel or polished wood. The width of the shelf and its material should be specified by the user

• Stainless steel cover for the arm rest. If it is ordered before shipping the table (in other words if the table is assembled with stainless steel covered arm rest instead of wooden arm rest), then it is free

• Vertical Spinning Disk Adaptor for 122 x 76 cm table

• Double-Storied (dual layer) Top Plate

• Upgradeable (into active pneumatic in the future) leg system

• Faraday-cage (2-door version, standing on its own feet, covered with perforated steel plates)

• Tool Set for Installing STable Active Pneumatic Vibration Isolation Tables

• Extended Warranty after the default 3 years for a STable Active Pneumatic Vibration Isolation Table

Quiet Air Compressor / Air Pump

There is a very popular and comfortable accessory of STable Active Vibration Isolation Tables: the Quiet Air Compressor. This air pump requires no adjustment or maintenance, but it can work for decades. The Quiet Air Compressor has got its internal pressure regulator circuit optimized to supply our Vibration Isolation Tables. The working actions of the air compressor make no pneumatic or mechanical disturbances for the table.

If there are no externally forced mechanical transients on the top plate of the STable Active Vibration Isolation Table, the air compressor starts itself a few times a day. A usual STable Active Vibration Isolation Table has got such tiny level of air leakage what starts the Quiet Air Compressor one or two times a day. If the Quiet Air Compressor starts itself more than five times a day, please call the repair service.

Technical Data

Default pressure range for the "small" tables:

Low (switch on) pressure: 2.0 Bar

High (switch off) pressure: 2.5 Bar

Default pressure range for the "large" tables:

Low (switch on) pressure: 5.0 Bar

High (switch off) pressure: 7.0 Bar

The default pressure ranges are optimized for STable Active Vibration Isolation Tables manufactured by Supertech Instruments. Other pressure range can also be specified in the order, because we manufacture Quiet Air Compressors for any user defined specification, for any 3rd-party table.

Volume of the internal air buffer tank: 3 dm3

Supply voltage: 230 VAC by default. We can manufacture 115 VAC versions upon unique requests.

Current consumption in the working periods: 1.6 A (at 230 VAC)

Peak current in the starting periods for approximately 2 seconds: 12 A (at 230 VAC)

Noise level: 40 dB(A). It is equal to the noise level of a usual household refrigerator.

Weight: 20 kg

Click on the picture to get it in full size

Important Notes About the Quiet Air Compressor / Air Pump

Quiet Air Compressor must always stand top side up! Quiet Air Compressor must not be tilted, because the internal lubricant oil would flow out on the tube connectors.

Quiet Air Compressor is not a dangerous equipment, but you should inspect it. If you recognize, that your Quiet Air Compressor starts more than three times a day, or even it works continuously, please stop it at once and do not switch it on again! In such a case please call the repair service immediately! A normally working Active Vibration Isolation Table starts the Quiet Air Compressor three times per day as maximum. The total worktime of the motor built into the Quiet Air Compressor is 1000 hours. It results, that the lifetime of the Quiet Air Compressor under normal conditions will be approximately 30 years. But if the motor works continuously, the 1000 hours means 41 days only! After spending the lifetime of the motor the Quiet Air Compressor can even catch fire!

If the motor stops, but the supply voltage is applied (it is the situation when a fault appears), the current of the motor is increased dramatically, resulting a very high temperature. There is an internal thermal protector fuse, what normally breaks the current in such a case. But this fuse can also become faulty in worst case, resulting a fire in your lab, and the building! That is, why you should inspect the Quiet Air Compressor periodically.

The starting current of the Quiet Air Compressor is approximately 12 A (at 230 VAC). It is decreased to the nominal 1.6 A in a few seconds after starting the motor, but it is necessary to connect the Quiet Air Compressor into a wall plug capable to provide 12 A of current.

Using Central Air Supply

It is much more secure to operate an Active Vibration Isolation Table from a Quiet Air Compressor, because the output pressure of the Quiet Air Compressor is controlled by its internal pressure regulator. It must never be higher than the absolute pressure limits of the gas supply (given at the Common Technical Data paragraph above). On every output connection point of the central air supply of the building there is always a pressure regulator installed. But that regulator is manually adjustable and can be turned up accidentally up to 8 or 10 Bar. The silicone rubber membranes of the table will immediately blow up above 2.5 Bar (or 7.5 Bar for the "large" tables)! We suggest you to use the Quiet Air Compressor as air supply in the system for the sake of the Table.

If you even decide to use the central air supply, please specify this fact in the order and we will provide the necessary safety adaptor for you.

Variable Shelf System

Variable Shelf System can be assembled either to the back side and/or on the left and/or right side of the table. The set consists of the steel pillars, the holding rods, three pieces of 40 cm deep shelves and their consoles. For every size of table we manufacture a back set and a side set. If you would like to build a Variable Shelf System on all sides (except for the front) of the table, you need to order one back and two side shelf sets. The back and the side shelf sets can be ordered independently of each other. This way you can build a customized arrangement of the measuring equipments around the vibration isolation table. All shelves are 40 cm deep. Maximal total mass load of one shelf is 300 N. The loads must be distributed on the shelves. Each console can keep 150 N, but the wooden shelf must not be loaded by 300 N in its middle.

| Size of the table | Width of the back shelves | Width of the side shelves |

| 98 x 66 cm | 90 cm | 60 cm |

| 150 x 98 cm | 140 cm | 90 cm |

| 180 x 149 cm | 170 cm | 140 cm |

For the measures of the Variable Shelf System of the 1500 x 980 mm vibration isolation table, please look at this sheet.

Click on the picture to get it in

full size

Click on the picture to get it in

full size

Hard vibration sources must be kept away from the Variable Shelf System. Please read the "Important Notes About the Bottom Shelf" paragraph, see below.

Stainless Steel Bottom Shelf

Stainless Steel Bottom shelf is used to keep some equipments of the microscope system under the top plate of the table. We manufacture such kind of shelf for every size of table. It is lain on the two lower horizontal beams of the leg system. If the bottom shelf is installed, it is impossible for a human to sit in front of the vibration isolation table, because there is not enough room for the legs of the user. Since most of the users watch the image of the microscope on a monitor instead of the ocular lens, it does not seem to be a real restriction.

| Size of the table | Depth of the bottom shelf |

| 98 x 66 cm | 20 cm |

| 150 x 98 cm | 50 cm |

| 180 x 149 cm | 88 cm |

Click on the picture to get it in

full size

Click on the picture to get it in

full size

Important Notes About the Bottom Shelf

Vibration isolation tables do not have infinite vibration suppression. That is, why hard vibration sources should be kept away from the table. Stainless Steel Bottom Shelf is in strong mechanical connection with the leg system of the table. You must not place any rude vibration source equipment neither on the Bottom Shelf, nor very close to a leg of the table. These "vibration dangerous" equipments are water heater/cooler, air heater/cooler, compressor, pump, electrode puller, microtome, power supply with big fan or with big mains transformer in it. Certainly, these equipments must not be put on the top plate (in other words in the vibration isolated environment), too.

Optical Hole Pattern

Optical hole pattern means: there are M6 threaded holes in 25 x 25 mm pattern on the top plate. It is an optional feature of the top plates. It is generally used on the top plates, because either the big equipments or the small optical elements (such as lenses, mirrors, lasers, etc.) can be positioned strongly and precisely. However in biological applications the top plate must be sanitizable and sterilizable. It would be impossible if optical hole pattern was drilled. This aspect is the reason, why we offer top plates with, without or partly drilled by the optical hole pattern. Any holes can only be drilled in our workshop during the manufacturing process of the top plates, it is not possible to do on-site.

Click on the picture to

get it in full size

Click on the picture to

get it in full size

If you order an optical hole pattern for the full surface of the top plate, we calculate the total area of the top plate as drilled area. The reason of this calculation method is, that the widths of the borders on the edges of the top plate depend on the size of the top plate, but the borders are surely smaller than 25 mm. If you order an optical hole pattern only on a specified, smaller area, we calculate the size of the drilled area as the area of the rectangular defined by the centers of the M6 holes in the corners.

Breadboards

Breadboard means: an additional thin plate containing M6 threaded holes in 25 x 25 mm pattern (optical hole pattern). The purpose of the breadboard is to provide optical hole pattern on such surfaces where holes have not been drilled originally. The breadboard can be placed on the top plate of the Vibration Isolation Table or on any other table. The breadboard is covered by dull stainless steel surface with special magnetic feature. We manufacture any size of breadboard. Its price is proportional to its size. The default thickness of the breadboard is 47 mm. Requests for other thicknesses are accepted for special applications.

It must be emphasized, that a breadboard can not substitute a top plate. The breadboard alone has not got enough bending stiffness and torsional rigidity. It is intended to be used on a stable surface (e.g. top plate of a vibration isolation table). Basically the stiffness (rigidity) is the difference between a top plate and a breadboard.

Special Shaped Hole on the Top Plate

You can order any special shaped, even big hole on the top plate. Such special holes can be necessary for example for a camera built to the bottom or base port of the microscope. We can make special shaped holes in the manufacturing phase of the top plate according to your specification and/or drawing. Below this is an example:

Click on the picture to

get it in full size

Vertical Spinning Disk Adaptor

Vertical Spinning Disk Adaptor is a breadboard, assembled vertically above the top plate of the STable Active Pneumatic Vibration Isolation Table. There are two strong pillars assembled to the sides of the top plate. These pillars hold the breadboard assembled vertically above (and a bit behind) the microscope. This very strong assembly is able to hold a heavy equipment (e.g. spinning disk) connected optically to the microscope. For the default measures of the Vertical Spinning Disk Adaptor for a 122 x 76 cm vibration isolation table, please look at these sheets.

Double-Storied (Dual Layer or Two Decker) Top Plate

A dual layer table is a usual active pneumatic vibration isolation table, but there is a smaller second breadboard standing on the top plate on height adjustable legs. We developed the dual layer table constructions for such applications where a heavy optical accessory should be connected to the microscope. An example is a spinning disk, if it is connected to the microscope on the side port. The microscope stands on the top plate on the usual way and the spinning disk unit is fixed on the second deck, on the higher breadboard. This is the reason, why the second deck is usually smaller than the top plate itself.

Double-Storied Top Plate can be added to any STable Active Pneumatic Vibration Isolation Table. Double-Storied Top Plate consists of any usual top plate, four pieces of height adjustable legs and a breadboard on the top of the height adjustable legs. Its dimensions, such as the height range of its four legs and the desired size of the breadboard should be specified in the order.

Click on the picture to get it in

full size

Click on the picture to get it in

full size

Faraday Cage

We manufacture any size of Faraday Cage. Our Faraday Cages have got two doors. The doors open to the left and right side, respectively. We do not manufacture other kind of door arrangements, but the Cage can be ordered without doors. Faraday Cage is covered with perforated steel plates. The steel material gives not only the basic function of Faraday Cages (electrostatic shielding), but it provides efficient magnetic shielding, too. The price of the Faraday Cage is proportional to the surface of the vibration isolation table manufactured for. The height has no effect on the price, it can be any custom value according to your space requirements. The effective height (the height of the shielded area what is covered by the steel plates) is 100 cm by default, unless other measure is specified.

In our product choice there are two kinds of Faraday Cages:

Big, stand-alone version

This version stands on its own feet, around the optical table. It is mechanically independent of the vibration isolated environment.

Small, table-top version

This version is connected to the top plate of the table. It is a part of the vibration isolated environment, because it moves together with the top plate.

You can download the Installation Manual of the Faraday Cage.

This is the big, stand-alone

version of Faraday Cage. Click on the picture to get

it in full size

Elastomeric Vibration Isolation Tables

There is a simplified vibration isolation method for such applications, which do not require high level of vibration attenuation. This method is based on specially designed elastomer elements. These elements can be used in our standard leg system instead of the pneumatic isolators. We have developed an upgradeable version, as well. The upgrade means: on-site changing of the elastomer isolator elements to active pneumatic isolators.

Maximum mass load of the Elastomer Set (4 pieces together): 2 kN, including the top plate.

Damping Plates

Damping Plates are elastomer-based vibration isolator equipments for such applications, which do not require high level of vibration attenuation. They can be put onto any given lab table. We manufacture the Damping Plates in two fixed sizes. You can see their detailed description on our IVF Vibration Isolation (IVF Table) page.

Big-load Elastomer Vibration Isolator Cone Unit

It is a practical vibration isolator element for self-designed or self-made vibration isolation devices. It can be used as a modular building block to make your own DIY anti-vibration system. The necessary number of Big-load Elastomer Vibration Isolator Cone Units built into a system depends on the mass load. Certainly in the aspect of isolation performance it is worse than the active pneumatic isolators. It is a good compromise for price sensitive applications or arrangements requiring simplicity.

Specifications / Technical Data

Nominal mass load of one unit: 400 - 500 N

Absolute maximum mass load of one unit: 600 N

Design height: 110 to 130 mm, adjustable by the M16 fixing screw

Design diameter: 120 mm

M16 male thread connector at the bottom side

Click on the picture to get it in full size

Small-load Elastomer Vibration Isolator Cone Unit

Specifications / Technical Data

Nominal mass load of one unit: 120 - 150 N

Absolute maximum mass load of one unit: 180 N

Design height: 60 mm

On-site Vibration Measurement Service

We offer on-site vibration measurement service, if a customer needs digitally recorded data of the vibration properties of a location or an equipment. We use a sophisticated 3-dimensional (X and Y horizontal, and Z vertical) accelerometer with extremely high sensitivity and wide recording bandwidth. Our accelerometer equipment employs the lowest noise vibration sensor available in the market in 2024. After the on-site measurement we provide either the time domain or the frequency domain density of the vibration at the location. This service can be especially useful in the following cases:

- Before the installation of any high magnification microscope system it is advisable to measure and evaluate the site of installation by comparing the measured vibration data to the allowed vibration specification of the microscope. This way a lot of efforts and annoyances can be avoided.

- There are special issues when some mysterious disturbance appears in the image recorded by the microscope. In such cases a vibration measurement with the industry's lowest noise and highest sensitivity sensor can help you to locate and identify the source of the unwanted vibration source.

Prices

You can find the general warranty and shipping conditions in the beginning of the Services page.

All prices of Supertech Instruments are public, except for the vibration isolation products. Most of the optical tables are sold by authorized reseller partners. We protect them this way. The current reseller prices of the products and services related to the vibration isolation topic are available in password protected PDF files. You can find these downloadable files close to the end of the Services page.

Shipment of the vibration isolation table, if it is transported by an independent, specialized lorry firm, on pallet:

- It is the default shipping method, cheap, fast and secure.

- For the availability to your target location and current price given by our partner firm, please email us.

The shipment means the insured shipping action up to the required location. The product is crated and shipped on pallet. Shipment does not include installation. We provide a detailed installation guide for every product. The installation does not need any special knowledge or practice.

For unique requests we offer on-site installation service. The planned installation date should be discussed at least 5 weeks in advance, otherwise it can not be guaranteed due to potential conflicts in third parties' (logistics firms, movers, etc.) scheduling.

Shipping of the vibration isolation table in the European Union, including complete installation is possible. On this service Supertech Instruments does NOT want to earn any profit, we just count and invoice our real expenses:

- Unit price of transportation: you can see the current value in the end of the Services page. This transportation fee is merely calculated from the price of fuel and the amortization rate of our vehicle and does not include any extra cost or profit. Since our factory is located in Hungary, the distance is calculated from the Hungarian factory to the target location and the same distance in backward direction.

- We provide a practiced service engineer as a driver. He can install the table fluently, he is not a simple driver. Alternately, our service engineer can travel by plane while the table is shipped on pallet.

- Moving specialists: for maximum safety third-party experts are contracted for heavy lifting during the installation process.

- Additionally, accommodation fee for our product specialist will be applied, if the distance from the Hungarian border is too long to travel there and back in one day (it is a particular consideration in every case).

FRAUD ALERT!

Last year Marquis Med Consulting GmbH, Owner: MARJAN VASIC (former microscopy sales leader), Company Registration Number: FN 551960g, VAT Number: ATU76581245, Tax Number: AT 09 383/5668, ordered a pneumatic vibration isolation table from Supertech Instruments. We shipped the table and provided 30 days payment terms after delivery. The deadline of the payment was expired. We gave him 4 months more delay, but the payment never arrived. Finally Mr. MARJAN VASIC informed us, that they do not want to pay at all.

(This warning was published just because we hate the fraudsters.)

Copyright @ Supertech Instruments - since 1991